Technics 1200 Service and Restoration

Where Can I Buy a Technics SL-1200 MK2?

If you want a fresh smelling Technics 1200 MK2 turntable then you can supply us with your equipment for restoration. Or we can search for a unit within your budget and restore to your specification. E.g. Colors, level of service, personalization. We do not release units back to clients until they are 100% functional and better than factory standards. Our powder coating color options are from Prismatic Powder Coating with over 6500+ colors to choose.Technics 1200 MK2 Service

History

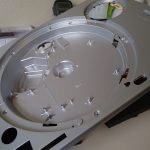

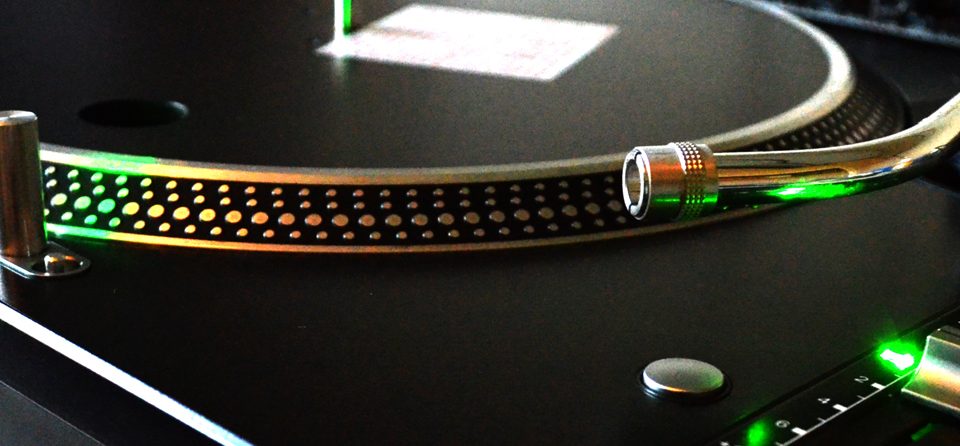

The Technics brand is one of best when it comes to DJ turntables. Dating back to the 1980’s with the iconic 1200’s but even in the 70’s with home equipment. We recently had the privilege to restore a Technics 1200 MK2. The turntable was in storage for a very long time and we mainly cleaned, repainted, replaced capacitors, upgraded to an LED pop up light, replaced the pitch fader and added gold plated RCA cables, reflowed solder after replacing a few transistors and capacitors. We also carried out a performance check to make sure the table didn’t have any issues while operating. These are the results.

Repair DJ Gear Service

We offer a wide spectrum of service, modifications, upgrades, personalization, and restoring. The direction really depends on your budget. We can really do anything.

There are a few new services and processes for the 2025 year.

Restoration Evaluation

Restorations and service require individual attention and vary greatly, from one to another. Based on the clients work request, an itemized quote will be created and approved before any work begins.

We see everything from units stored in cases for decades to units that have been used in home, the club and thrown or dropped. We have seen it all. And all of them are restored back to a better operating condition.

*5 to 7 hour process

Disassemble chassis to plinth.

Clean & calibrate tonearm adjustment assembly.

Check tonearm antiskating mechanism. Adjust if necessary.

Calibrate tonearm pivot bearings & lubricate if needed.

Replace audio cables with Mogami W2528 dual unbalanced cable and Neutrik NYS373 Gold Plated Series RCA’s

Replace pitch slide potentiometer with new, SFDZ122N11-2 or equivalent.

Calibrate pitch gain to 262k frequency.

Check & service target lamp mechanical components. Lubricate as needed. Upgrade to LED.

Check condition of tonearm base, power switch, start/stop button, 33/45 buttons. Clean.

Observe pitch zero. Calibrate.

Reflow solder joints on main PCB to avoid known issues.

Check and replace leaking capacitors.

Check voltage regulator and resistor. Replace. (Transistor for power and strobe – Q2, Q3, Q201 Resistor R307).

Check, clean and lubricate center spindle.

Speed stability & torque test.

Calibrate brake adjust.

Replace pitch slide felt.

Reassemble & clean turntable parts.

Resurface platter dots.

Soak test.

Tonearm holder replaced with new.

Powder coat

Personalized paint

Base colors

Pearl colors

Technics typography reprint

Personalized lettering

Personalized graphics

Cerakote

Clear coat

One Color – Media blasted platter and masked.

Two Color – Media blasted, masked off, and multiple step process.

Plating – Gold plating or diamond / crystal placement.

Two Stage Cerakote Finish

Tonearm Base – A few options to leave as is but with full service. Powder coating is extensive due to the masking off of holes and bearings. The tonearm base has three parts to be color changed.

Tonearm Assembly – Typically left chrome. Any color combination is available.

Let us know what you desire! We make it happen.